Maths, Physics & Chemistry

Maths, Physics & Chemistry

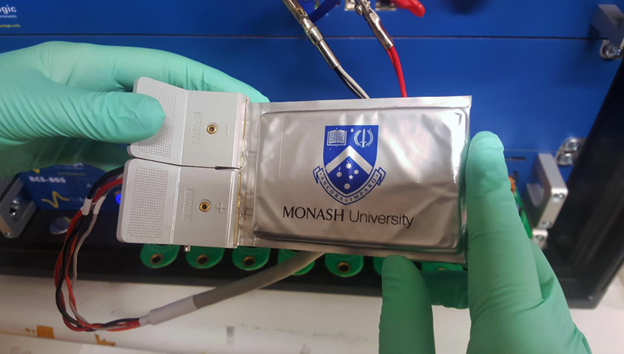

Stress management in lithium-sulfur battery: some space to breathe

Lithium-Sulfur battery can store more energy than the commonly-used Li-ion battery. But the high capacity of the Sulfur electrode causes it too much stress and it quickly breaks apart, in the same way we might when placed under stress. We engineered an open architecture, which gave sulfur particles space to breathe, thus stabilized the electrode, taking them closer to mass adoption.

Lithium-ion batteries, of the type we can find in any house-hold, have changed the world. But as society moves away from fossil fuels, we will need cheaper and greener technologies for storing energy to support renewable electricity generation and electric vehicles. The Lithium-Sulfur (Li-S) battery is at the forefront of competing battery technologies by offering more energy for a given weight, at a lower price and CO2 footprint. The Li-S battery uses cheap sulfur as the positive electrode and the ultra-high-capacity lithium metal as the negative electrode.

Lightweight Li-S batteries have recently made great progress, reaching energy output in the range of 400-450 Watt-hour per kilogram. Such high energy output can unlock several application avenues, in particular in the aviation industry where lighter batteries are key. These may include unmanned aerial vehicles, as well as the multi-million-dollar industries of drone delivery and agricultural drone spraying. For example, agricultural spray drones have numerous advantages over traditional tractor boom sprays but have been limited in their ability to cover large areas, often having a maximum total flight time of 15 min before the battery needs to be replaced and recharged. Lightweight Li-S batteries could potentially boost this industry by increasing the flight time.

The high energy Li-S batteries, however, have not been able to attract a significant market yet. The main challenge to the mass adoption of Li-S battery is its short life which is mainly linked to the rapid degradation of both electrodes.

A person may feel pressure if the demands of their job exceed their capabilities, which could lead to a drop in productivity or performance. In the same manner a battery electrode asked to store a lot of energy may be subjected to increased stress.

In an Li-S battery, energy is stored when positively charged lithium ions are absorbed by an electrode made of sulfur particles that are embedded in a carbon matrix and held together with a polymer binder. The carbon matrix is a vital component of the battery that delivers electrons to the sulfur particles, and the polymer glues the sulfur and carbon together. Together, they provide electrons a path to move across, similar to the way current runs through electrical wiring.

The high storage capacity means that the electrode swells up to almost double its size when fully charged. The cycle of swelling and shrinking as the battery charges and discharges leads to a progressive loss of cohesion of particles and permanent distortion of both the carbon matrix and the polymer binder. When they are distorted, the electrons' paths are destroyed and the battery's performance decays very quickly.

The conventional way of producing batteries creates a continuous dense network of binder across the bulk of the electrode, which doesn't leave much free space for movement. This method works for lithium-ion batteries, but for Li-S batteries we had to develop a new technique.

To make sure our batteries would be easy and cheap to manufacture, we used the same material as a binder but processed it differently. The result is a web-like network of binder that holds particles together but also leaves plenty of space for material to expand. These expansion-tolerant electrodes can efficiently go through multiple cycles of charging and discharging, allowing the sulfur particles to live up to their full energy storage capacity.

Our results show that expansion-tolerant sulfur electrodes provide a powerful tool. However, the instability issues of the other electrode, the lithium, is yet to be fully resolved by battery scientists. In fact, the introduction of this revolutionary energy storage technology to the marketplace without significant development on the protection of the lithium electrode is unlikely. The stabilizing of the lithium electrode is absolutely necessary for long-lasting, inexpensive, and safe Li-S batteries.

We gave the Sulfur particles some space to cope with the stress. To do so, we didn't introduce any new materials and didn't sacrifice the working capacity; We employed a traditionally used binder but processed it differently to create an open structure. Giving someone space to increase their capability to cope without sacrificing their capacity may be as simple if we engineer the situation in the same subtle fashion.

Original Article:

1. Shaibani M, Mirshekarloo MS, Singh R, et al. Expansion-tolerant architectures for stable cycling of ultrahigh-loading sulfur cathodes in lithium-sulfur batteries. Sci Adv. 2020;6(1):eaay2757.

Edited by:

Dr. Ayala Sela , Associate Editor

We thought you might like

Gotta recognize ‘em all! Using Pokémon to understand brain development

Nov 19, 2019 in Neurobiology | 3.5 min read by Jesse GomezVicious Circles – how changes in the shape of DNA can drive cancer

Aug 17, 2020 in Health & Physiology | 3.5 min read by Sihan Wu , Paul S. MischelProbing the evolution of photosynthetic life on the early Earth

Jun 19, 2018 in Plant Biology | 3 min read by Andrew H. KnollThe mystery of an ancient reptile with a ridiculously long neck

Feb 8, 2021 in Evolution & Behaviour | 4 min read by Stephan SpiekmanMore from Maths, Physics & Chemistry

Testing gravity through the distortion of time

Sep 20, 2024 in Maths, Physics & Chemistry | 3 min read by Sveva CastelloStacking molecular chips in multiple dimensions

Aug 30, 2024 in Maths, Physics & Chemistry | 3 min read by Lucía Gallego , Romain Jamagne , Michel RickhausReversible Anticoagulants: Inspired by Nature, Designed for Safety

Jun 12, 2024 in Maths, Physics & Chemistry | 4 min read by Millicent Dockerill , Nicolas WinssingerDistance-preserving moves always keep a point fixed

May 18, 2024 in Maths, Physics & Chemistry | 4 min read by Shaula FiorelliA resonance triggers chemical reactions between the coldest molecules

Apr 5, 2024 in Maths, Physics & Chemistry | 3 min read by Juliana Park , Wonyl ChoiEditor's picks

Trending now

Popular topics