Vitamin A deficiency impacts millions globally. Directly adding it to foods is problematic due to its sensitivity to light and heat. We've created an edible microparticle ensuring safe vitamin A delivery. These microparticles are stable and offer high absorption rates, presenting a groundbreaking solution to combat vitamin A deficiency and degradation globally.

Views 2675

Reading time 4 min

published on Oct 27, 2023

Vitamin A is crucial for our ability to see, fight off diseases, and for babies to grow healthily. Vitamin A is currently the second most deficient micronutrient among the malnutrition population globally, just after iron. Vitamin A deficiency (VAD) causes blindness in children and increases the risk of death due to infectious diseases. The World Health Organization (WHO) estimated that about one-third of the global population of preschool-aged children suffers from VAD.

WHO implemented the global vitamin A supplementation program in 1990, distributing high-dose vitamin A capsules to children every 4 to 6 months. Despite these efforts, millions of children and pregnant women still suffer from VAD, highlighting the urgent need for more effective solutions.

Consuming a small amount of vitamin A everyday ensures a good uptake and has been proven to be a more efficient way to increase the vitamin A content in the body. Therefore, adding vitamin A to staple food is, potentially, a more impactful strategy for defeating VAD worldwide.

Yet, the fortification of vitamin A is not easy. Firstly, vitamin A is oil-like, hindering its direct amalgamation with dry foods. Secondly, Vitamin A breaks down easily when exposed to air, light, or heat, making it difficult to add to foods without losing its benefits. The high temperature and high humidity during cooking and storage can further accelerate the breakdown of vitamin A, destroying the vitamin A in food before it is consumed.

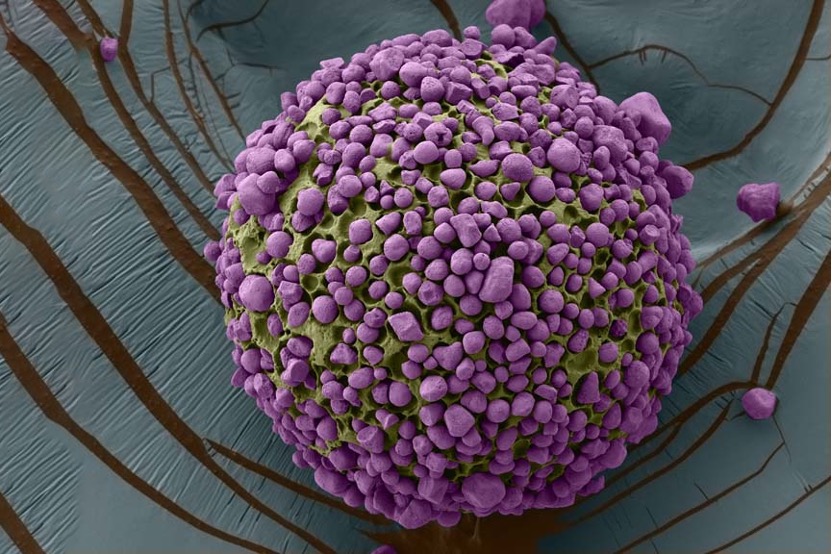

We developed an edible microparticle that can be easily combined with dry food, protects vitamin A from degradation during storage and cooking, and can be readily absorbed after ingestion in humans. The study was recently published in the Proceedings of the National Academy of Sciences. This new technology could revolutionize the way we address vitamin A deficiency, making it easier to get this vital nutrient to those who need it most.

In 2019, we identified a material called BMC from fifty polymers to encapsulate a wide range of nutrients. BMC is an FDA-approved polymer and has a specific pH-controlled solubility. In water, BMC is not soluble, but in acidic water, such as stomach fluids, BMC quickly dissolves and releases the essential micronutrients.

The microparticles, composed of vitamin A and BMC, were created using the spinning disc process and were then coated with starch to ensure protection from light. The stability of vitamin A in microparticles during cooking (100 oC in boiling water) for up to five hours was largely improved compared to free vitamin A and VitA 250, which is the vitamin A microparticle currently used in food fortification. We also simulated cooking with copper ions, an oxidative species abundant in seafood and meat. Our vitamin A microparticles retained their great stability, while that of VitA 250 dramatically decreased.

Half-life, or the time for half of the compound to degrade, is used to indicate the stability of vitamin A microparticles after it is mixed in a bouillon cube. In tropical climate (40oC and 75 percent humidity), the half-life of our vitamin A microparticle is 333 days, while that of VitA 250 is about 81 days.

After determining its outstanding heat stability, the absorption of vitamin A from microparticles was validated through in vitro, in vivo, and human studies. When rats consumed our BMC vitamin A microparticles, cooked or uncooked, the absorption level remained similar to the uncooked vitamin A, while the absorption levels were much higher compared to cooked unencapsulated vitamin A. These results indicate our vitamin A microparticles are highly stable and can be easily absorbed after ingestion in animals.

The strongest evidence for the absorption of encapsulated vitamin A comes from the clinical trial carried out in the United States by MIT and Biofortis. The bread made of vitamin A-fortified flour was given to 32 women, and the vitamin A level in their blood was monitored over a 24-hour period. The encapsulated vitamin A resulted in a comparable absorption level to free vitamin A, and it was not influenced by the codelivery of encapsulated iron and free folic acid. These results exemplified that our microparticles can effectively deliver vitamin A, even when combined with other nutrients, revealing new possibilities for treating nutrient deficiencies worldwide.

Ideally, we envision our microparticles as rainbow sprinkles that are easily added to different types of food, magically ensuring the food contains all the necessary nutrients. This could revolutionize the way we address nutrient deficiencies, potentially improving the health of millions of people around the world.

Original Article:

Tang, W.; Zhuang, J.; Anselmo, A. C.; Xu, X.; Duan, A.; Zhang, R.; Sugarman, J. L.; Zeng, Y.; Rosenberg, E.; Graf, T.; McHugh, K. J.; Tzeng, S. Y.; Behrens, A. M.; Freed, L. E.; Jing, L.; Jayawardena, S.; Weinstock, S. B.; Le, X.; Sears, C.; Oxley, J.; Daristotle, J. L.; Collins, J.; Langer, R.; Jaklenec, A. Enhanced stability and clinical absorption of a form of encapsulated vitamin A for food fortification. Proc. Natl. Acad. Sci. U. S. A. 2022, 119, e2211534119.

Health & Physiology

Health & Physiology